B. Com

40 Years Working Experience

K. PARAL & CO.

About Us

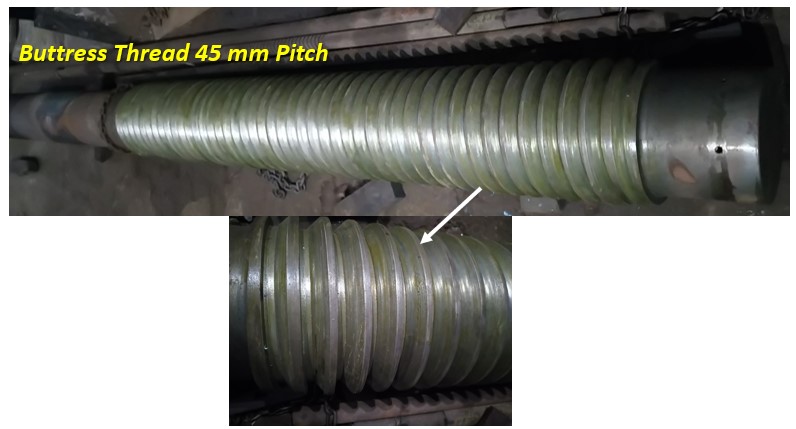

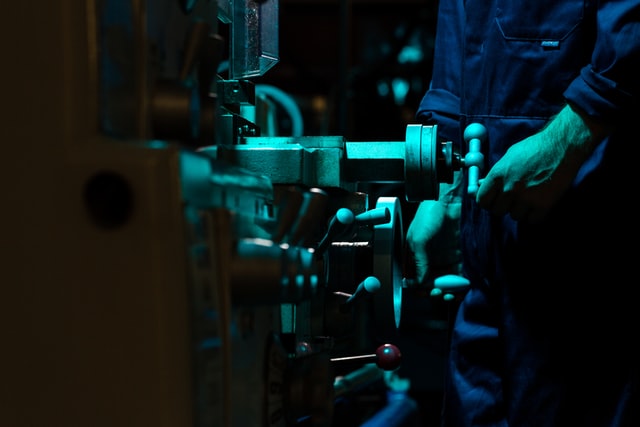

K.PARAL & CO., (since 1992) serves the heavy-duty machining job without compromising the product quality and maintaining a good acquaintance in a great manner. The company is located at Dasnagar, West Bengal, eastern part of India which city was called “Birmingham of India” during the British territory. The company serves the heavy machining jobs like Eccentric Shaft, Lead Screw, Propeller Shaft, Roller Shaft, Pump Shaft, Gun Metal Bush, Multi Point Thread Cutting (ACME, Metric, BSW, Square, Buttress), Hydraulic Cylinder Bore Grinding, etc. with focusing the Geometric Dimensioning and Tolerancing (GDT) as well as delivery time period.

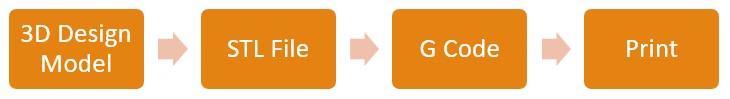

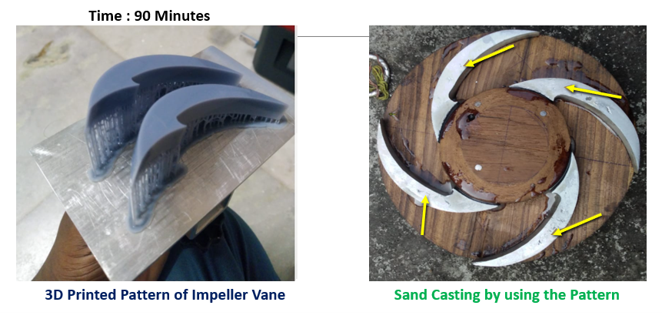

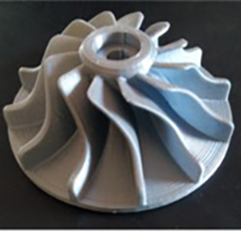

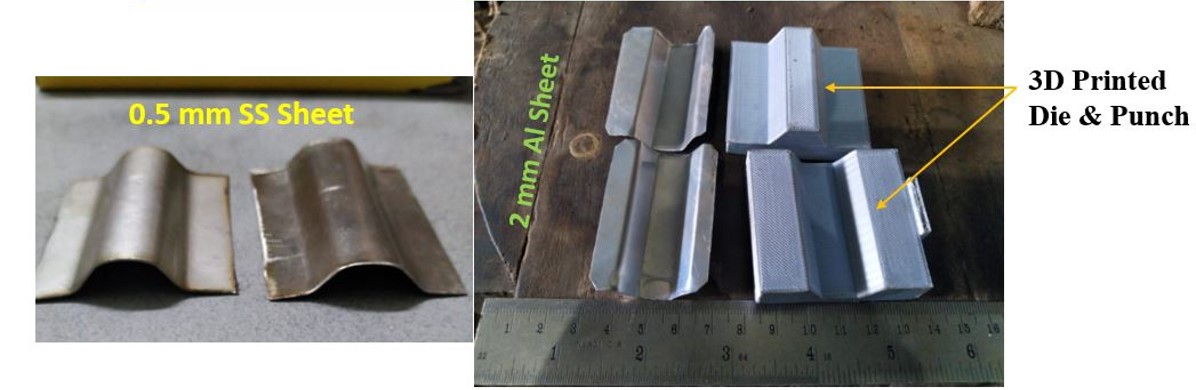

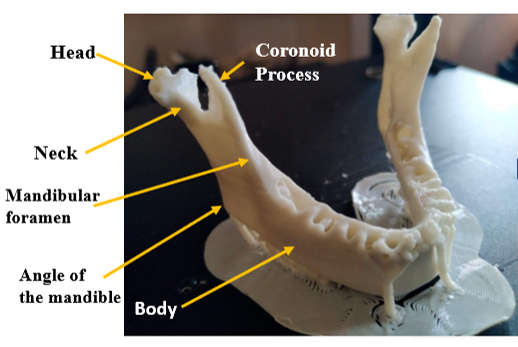

From 2020, Sandeep Kumar Paral (M.Tech(JU), ME) has taken the initiative of the application of Additive Manufacturing technology (3D Printing) as well as market analysis of the field of utilization by which it can be implemented in a great manner. Manufacturing industries, Medical fields (especially in dentistry), Jewelry sectors have been very much influenced in terms of product complexity, rapid customization, design flexibility, and minimizing the tooling cost. Additive Manufacturing is one of the latest inventions which boosts up the RD and is also an important feature of Industry 4.0.

Managing Body

Kashi Nath Paral

ProprietorSandeep Kumar Paral

Q.C. & Production ManagerM. Tech (JU)

RD experience in Taiwan

Ranodip Paral

SupervisorDiploma Engg.

Additive Manufacturing Section

Sandeep Kumar Paral

Product DevelopmentM. Tech (JU)

RD experience in Taiwan